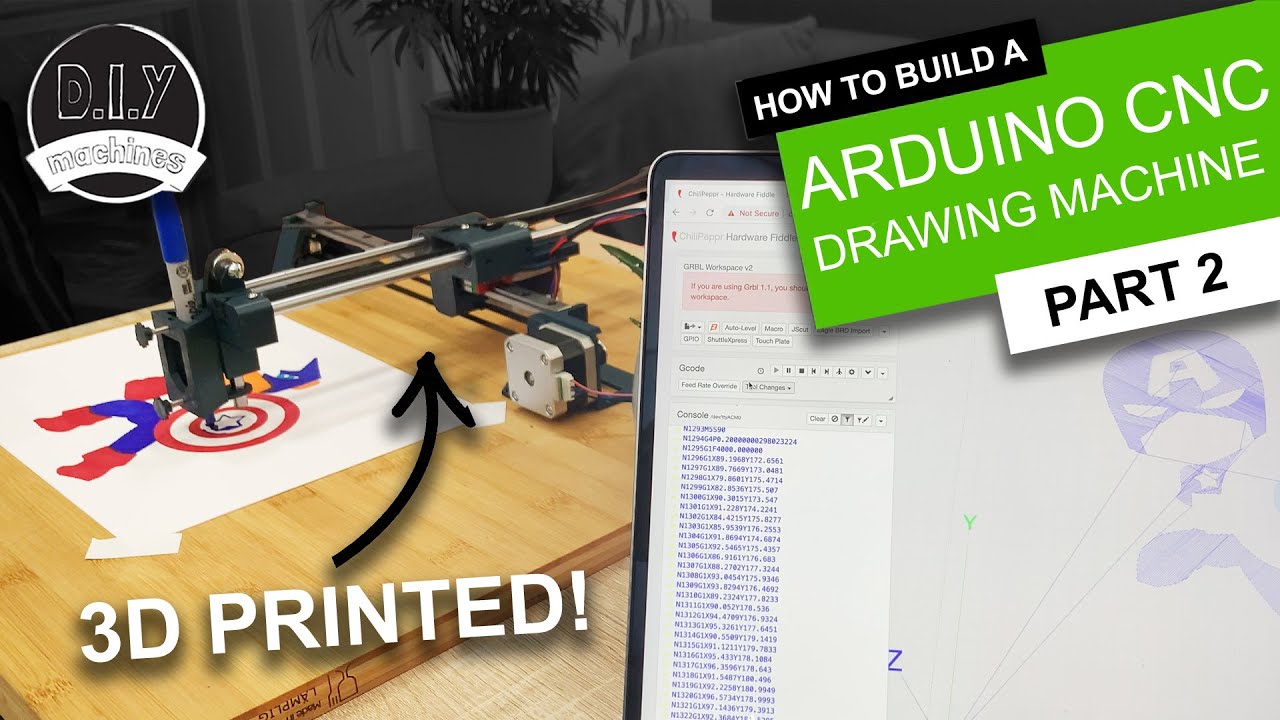

Super Easy 3D Printed Arduino CNC Drawing Machine - P2 - The Software | GRBL | Inkscape Plotter

Learn how to upload and configure GRBL to your Arduino CNC machine. I'll also help you test it and then show you how to create your own artwork. ? More info below ?

Part One for this project (which guides you through the 3D printing and assembly) can be found here: https://youtu.be/XYqx5wg4oLU

List of items used in this project and where to find them:

■ 8 x15 x 45mm Linear Bearing (x2): https://geni.us/LinearBearing45mm

■ 8 x 15 x 25mm Linear Bearing (x1): https://geni.us/LinearBearing25mm

■ 12v Nema 17 stepper motors (x2): https://geni.us/StepperMotor

■ GT2 Timing belt and pulleys: https://geni.us/TimingBelt5m

■ Micro servo (x1): https://geni.us/MicroServo

■ Elegoo Arduino Uno (x1): https://geni.us/ArduinoUno

■ Nuts, bolts and screws (See list below): https://geni.us/NutsAndBolts

■ Stepper drivers - TMC2208 (x2): https://geni.us/TMC2208

■ Contact switch (x2): https://geni.us/ContactSwitch

■ Arduino CNC Shield (x1): https://geni.us/ArduinoCNCShield

■ 30mm 5V Fan (x1): https://geni.us/30mm5vFan

■ 8mm Chromed Steel Rod (35cm x2 & 5.5cm x1): https://geni.us/8mmChromedSteelRod

■ 30cm long linear rail with block (x1): https://geni.us/LinearRail300mm

■ Electrical wire: https://geni.us/22AWGWire

■ 12v power supply - 2A or greater (x1): https://geni.us/12VPowerSupply2A

■ 6mm Idler Wheel - 3mm Bore (1): https://geni.us/6mmIdlerWheel3mmBore

■ Wooden panel to mount project at least 36x42cm (I used an Ikea ‘LÄMPLIG’ chopping board)

■ Sharpie Pens: https://geni.us/Sharpie

Nuts, bolts and screws needed:

■ M5 x 25mm (x2)

■ M3 x 18 (x3)

■ M3 x 12 (x2)

■ M3 x10 (x3)

■ M3 x 6 (X14)

■ M3 nuts (x9)

■ M5 nut (x1)

■ Short wood screws (x8)

These are some of my favourite tools I use and can recommend:

■ Battery-powered glue gun: http://geni.us/BoschBatteryGlueGun

■ Bosch Bit Driver: https://geni.us/Bosch-Screwdriver

==========

The code, wiring diagrams, 3D printable parts etc can be downloaded for free from here:

https://www.diymachines.co.uk/arduino-cnc-drawing-machine

The drawings I created for use with my machine:

https://lewisaburrow.selz.com/item/5f06e0e7701f5d08645fa511

Inkscape 0.48.5 for Windows:

https://inkscape.org/release/inkscape-0.48/?latest=1

==========

SAY THANKS:

Provide continual and dependable support through Patreon:

Support us on Patreon: https://www.patreon.com/diymachines

Buy me a coffee to say thanks: https://ko-fi.com/diymachines

SUBSCRIBE:

■ https://www.youtube.com/channel/UC3jc4X-kEq-dEDYhQ8QoYnQ?sub_confirmation=1

INSTAGRAM: https://www.instagram.com/diy_machines/?hl=en

FACEBOOK: https://www.facebook.com/diymachines/

==========

List of camera and lighting equipment I use:

Sony A7 III: https://geni.us/Sony-Alpha7-III

Tamron 28-75mm F2.8 RXD A036SF Lens for Sony-FE : https://geni.us/TamronRXD-28-75mm

Aputure Amaran HR672C: https://geni.us/AputureAmaranHR672C

Aputure MC: https://geni.us/FAPGL

RØDE VideoMic Pro+: https://geni.us/RodeVideoMic-ProPlus

Blue Snowball iCE: https://geni.us/BlueSnowball-iCE

Philips Hue Lightstrip Plus: https://geni.us/PhilipsHue-LightStrip

Disclaimer:

This video is shared for demonstration purposes only.

Part One for this project (which guides you through the 3D printing and assembly) can be found here: https://youtu.be/XYqx5wg4oLU

List of items used in this project and where to find them:

■ 8 x15 x 45mm Linear Bearing (x2): https://geni.us/LinearBearing45mm

■ 8 x 15 x 25mm Linear Bearing (x1): https://geni.us/LinearBearing25mm

■ 12v Nema 17 stepper motors (x2): https://geni.us/StepperMotor

■ GT2 Timing belt and pulleys: https://geni.us/TimingBelt5m

■ Micro servo (x1): https://geni.us/MicroServo

■ Elegoo Arduino Uno (x1): https://geni.us/ArduinoUno

■ Nuts, bolts and screws (See list below): https://geni.us/NutsAndBolts

■ Stepper drivers - TMC2208 (x2): https://geni.us/TMC2208

■ Contact switch (x2): https://geni.us/ContactSwitch

■ Arduino CNC Shield (x1): https://geni.us/ArduinoCNCShield

■ 30mm 5V Fan (x1): https://geni.us/30mm5vFan

■ 8mm Chromed Steel Rod (35cm x2 & 5.5cm x1): https://geni.us/8mmChromedSteelRod

■ 30cm long linear rail with block (x1): https://geni.us/LinearRail300mm

■ Electrical wire: https://geni.us/22AWGWire

■ 12v power supply - 2A or greater (x1): https://geni.us/12VPowerSupply2A

■ 6mm Idler Wheel - 3mm Bore (1): https://geni.us/6mmIdlerWheel3mmBore

■ Wooden panel to mount project at least 36x42cm (I used an Ikea ‘LÄMPLIG’ chopping board)

■ Sharpie Pens: https://geni.us/Sharpie

Nuts, bolts and screws needed:

■ M5 x 25mm (x2)

■ M3 x 18 (x3)

■ M3 x 12 (x2)

■ M3 x10 (x3)

■ M3 x 6 (X14)

■ M3 nuts (x9)

■ M5 nut (x1)

■ Short wood screws (x8)

These are some of my favourite tools I use and can recommend:

■ Battery-powered glue gun: http://geni.us/BoschBatteryGlueGun

■ Bosch Bit Driver: https://geni.us/Bosch-Screwdriver

==========

The code, wiring diagrams, 3D printable parts etc can be downloaded for free from here:

https://www.diymachines.co.uk/arduino-cnc-drawing-machine

The drawings I created for use with my machine:

https://lewisaburrow.selz.com/item/5f06e0e7701f5d08645fa511

Inkscape 0.48.5 for Windows:

https://inkscape.org/release/inkscape-0.48/?latest=1

==========

SAY THANKS:

Provide continual and dependable support through Patreon:

Support us on Patreon: https://www.patreon.com/diymachines

Buy me a coffee to say thanks: https://ko-fi.com/diymachines

SUBSCRIBE:

■ https://www.youtube.com/channel/UC3jc4X-kEq-dEDYhQ8QoYnQ?sub_confirmation=1

INSTAGRAM: https://www.instagram.com/diy_machines/?hl=en

FACEBOOK: https://www.facebook.com/diymachines/

==========

List of camera and lighting equipment I use:

Sony A7 III: https://geni.us/Sony-Alpha7-III

Tamron 28-75mm F2.8 RXD A036SF Lens for Sony-FE : https://geni.us/TamronRXD-28-75mm

Aputure Amaran HR672C: https://geni.us/AputureAmaranHR672C

Aputure MC: https://geni.us/FAPGL

RØDE VideoMic Pro+: https://geni.us/RodeVideoMic-ProPlus

Blue Snowball iCE: https://geni.us/BlueSnowball-iCE

Philips Hue Lightstrip Plus: https://geni.us/PhilipsHue-LightStrip

Disclaimer:

This video is shared for demonstration purposes only.

DIY Machines

How to build awesome machines using affordable components.

Our aim is simple, to bring easy to re-create projects whilst keeping the cost low. By designing custom 3D printable components as much as possible means that if you have access to a 3D printer, ...